Being prominent ceramic fiber products producer and exporter in India, we are using refractory fibers and binders for producing our Ceramic fiber board.

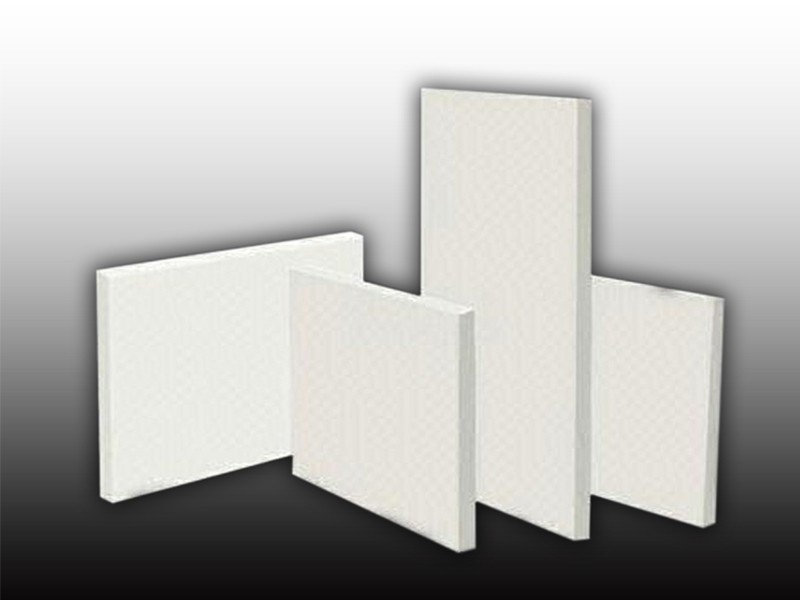

Divine Cera Ceramic Fiber Board is made of ceramic bulk fiber with special formulated binder and produced by vacuum formed technology. The board has excellent toughness and intensity, high strength, lightweight, excellent thermal shock resistance and anti-stripping.

Divine Cera Ceramic Fiber Board can be widely used for insulation in the linings around and at the bottom of kilns, as well as ceramic kilns fire position, craft glass mold and other positions. Temperature varies from LT-1050℃(1930°F), RT-1260°C (2300°F) and HTZ-1425°C (2600°F). It is available in a wide variety of thickness, widths and densities.